2 Hardware Overview

2.1 Arm

2.1.1 Overview

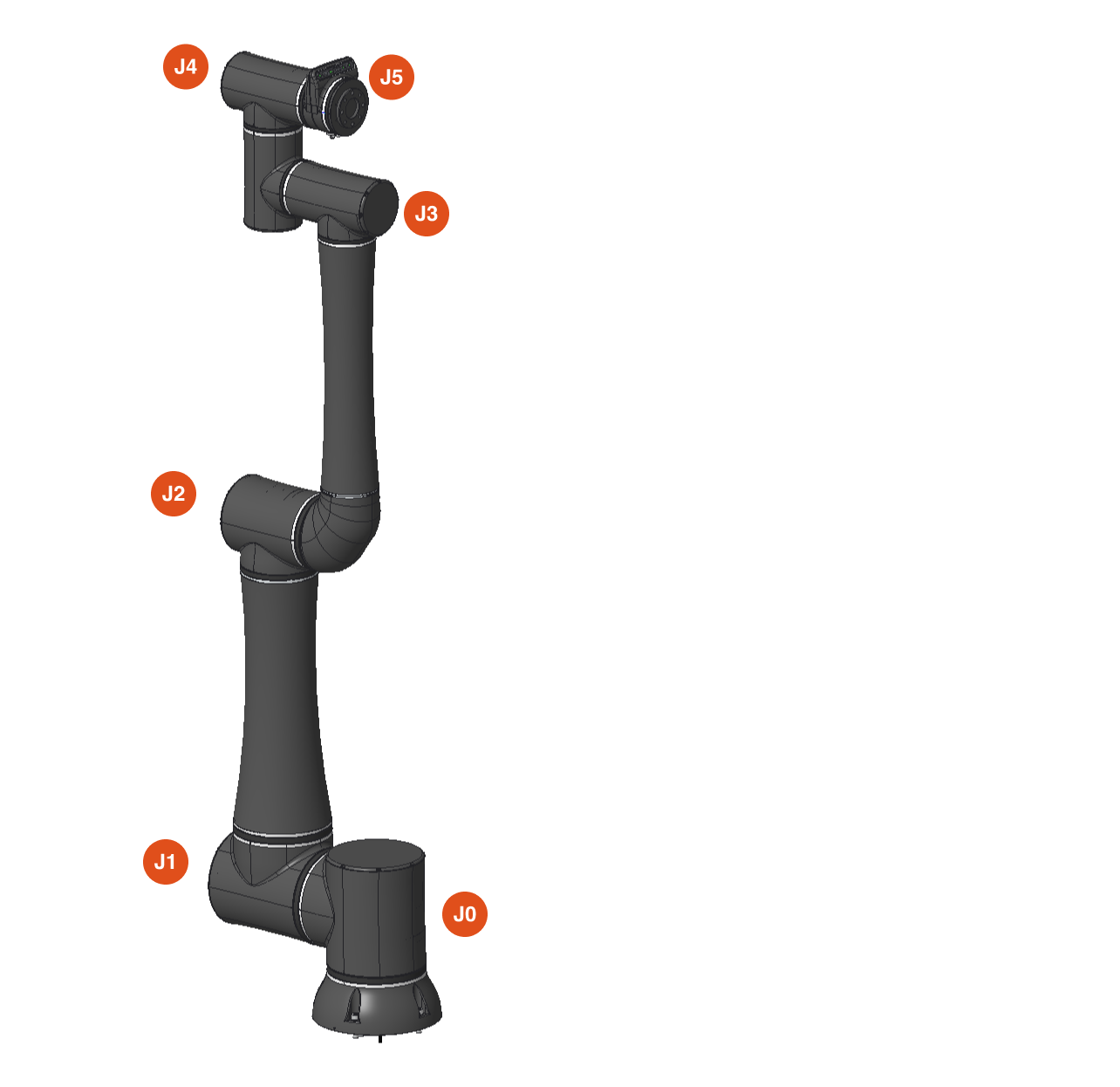

The RO1’s arm contains 6 joints connected by a CAN bus. Each joint has two encoders, two different methods to sense torque, and fail-safe brakes that provide emergency braking torque when power is removed from the arm

2.1.2 Reach

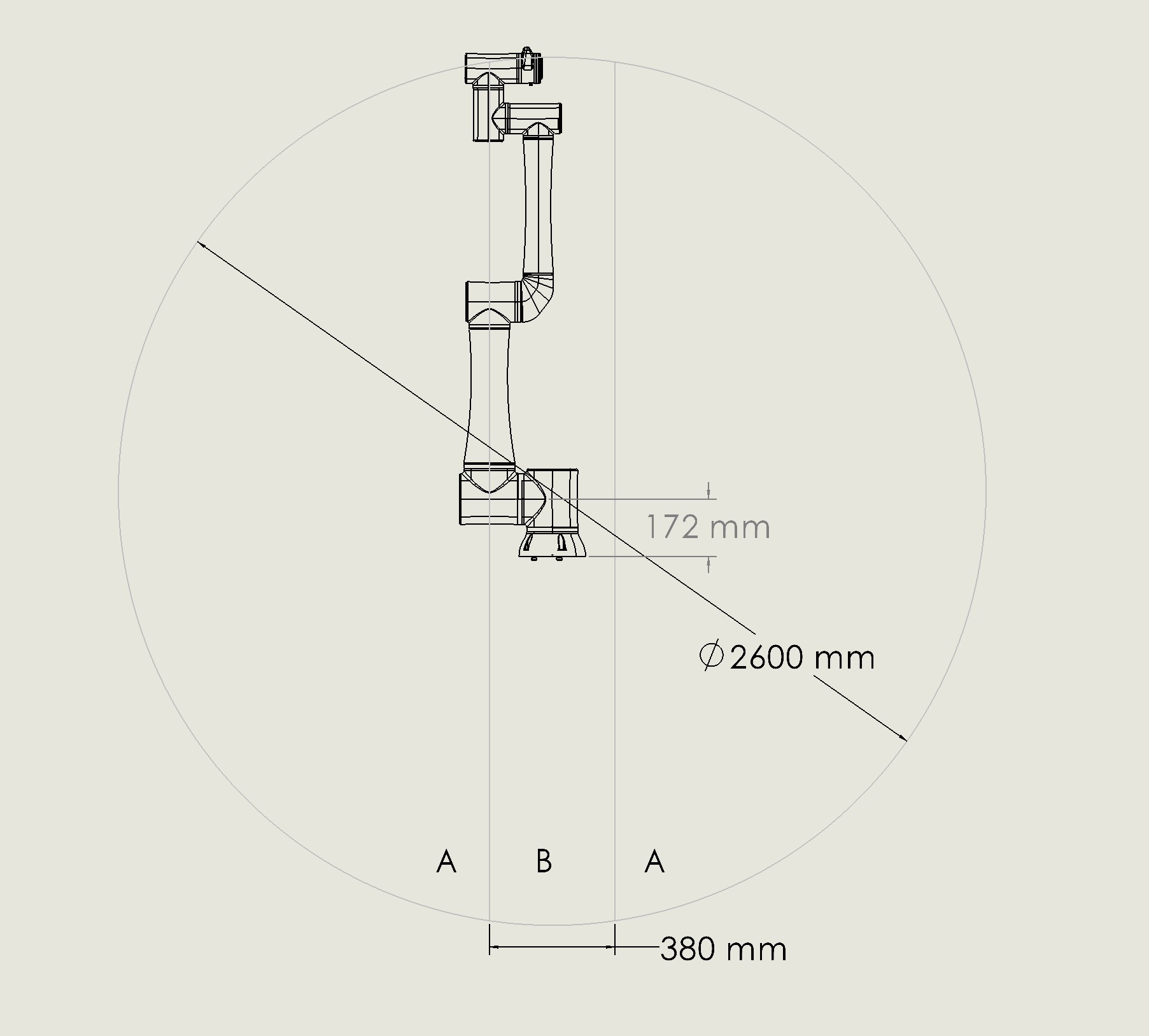

The RO1 robot can reach 1300 mm (51 in) in a radius from the center of the base (A). There is a radius from the center base of 190 mm (7.5 in) (B) where the robot cannot reach due to it’s structure. Tools added to the robot end of arm will impact the reach of the robot.

2.1.3 Payload Chart

Footnotes:

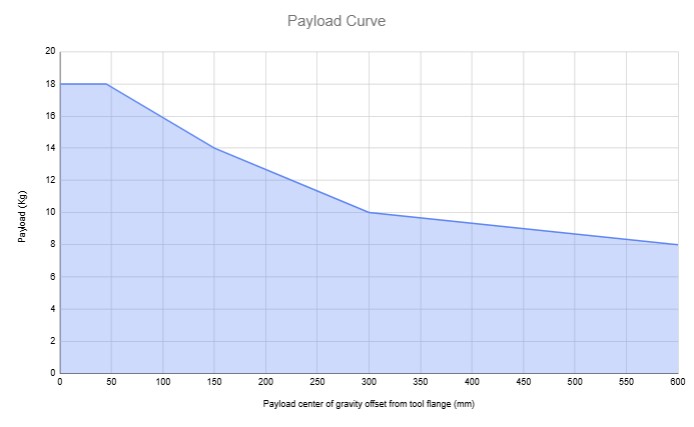

- At payloads above 16kg, the maximum speed of the robot will be reduced to 25% of the default speed settings. The default tooltip speed is .75 m/s.

- At payloads above 16kg, the weight limit may be reduced if the routine includes stops with the arm near full extension.

- The above chart assumes near ambient room temperature. Running the robots in warmer environments will reduce the payload capacity.

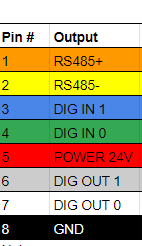

2.1.4 Tool Flange Pinout

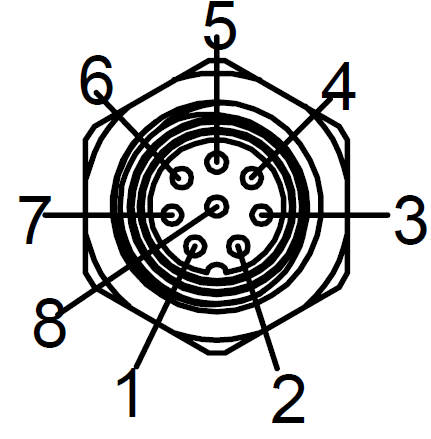

The current limit on the 24V DC line of the flange is 3 amps. The flange is capable of PNP or NPN operation and is auto switching. The pinout at the end of the Tool Flange is laid out as shown:

Also, please not that the 4-pin connector at the tool flange is not currently supported.

2.1.5 LED Colors

The robot end of arm has an LED status light for assisting in determining the robot status. The color codes are as follows:

| Robot State | Color |

|---|---|

| Idle or Paused | Solid Green |

| Bootup / Startup | Color Cycle |

| Full Speed (above collaborative threshold in Safety Settings) | Yellow Ring Pattern |

| Reduced Speed (below collaborative threshold in Safety Settings) | Solid Yellow |

| Antigravity Mode | Solid Blue |

| Firmware Update | White Ring Pattern |

| Recoverable Error | Red Pulsing |

| Fatal Error | Braked |

2.2 Control Box

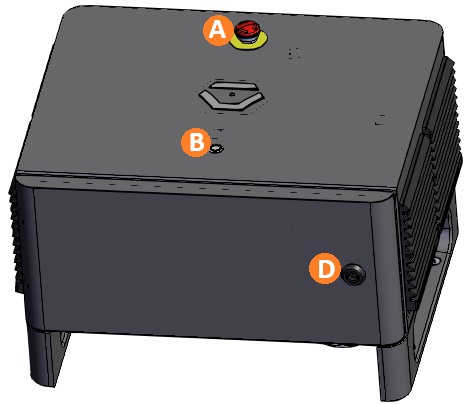

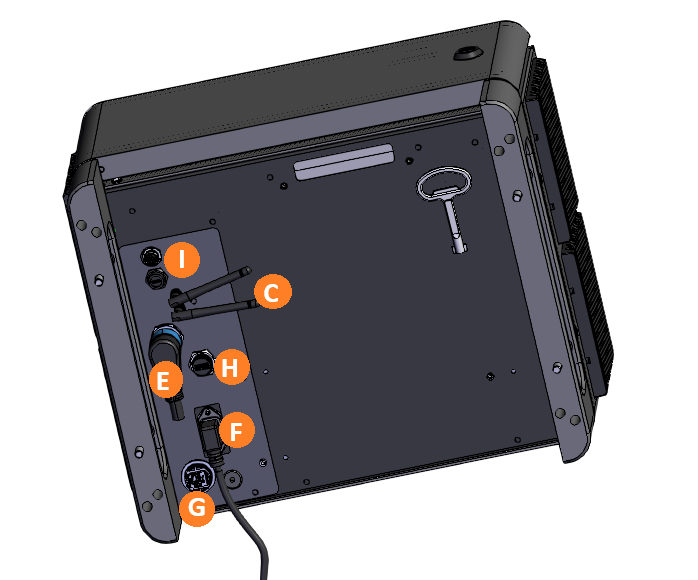

There are several features to note on the control box:

| Item | Name | Description |

|---|---|---|

| A | E-Stop | Pressing the E-stop button initiates an emergency (category 1) stop, cutting power to the arm. Twist the button to reset it. |

| B | Button Control | Turn on button |

| C | Bluetooth & Wi-Fi Antennae | The R01 ships with two antennas that can be screwed into the top to give the control box access to Bluetooth and Wi-Fi. Bluetooth is used to pair the tablet. |

| D | Lock & Key | The RO1 includes a key that can be used to lock the control box door. |

| E | Arm data + power connection | This links the control box to the arm. Power to the arm runs at 48V |

| F | Power | The control box accepts 120V through a power supply module already certified to IEC 62368-1 and FCC EMI limits. |

| G | Ethernet (RJ45) | This can be used to communicate with other devices in the cell, or to the tablet for programming |

| H | USB-A port | |

| I | USB-C port | This links the control box to the camera on the robot arm |

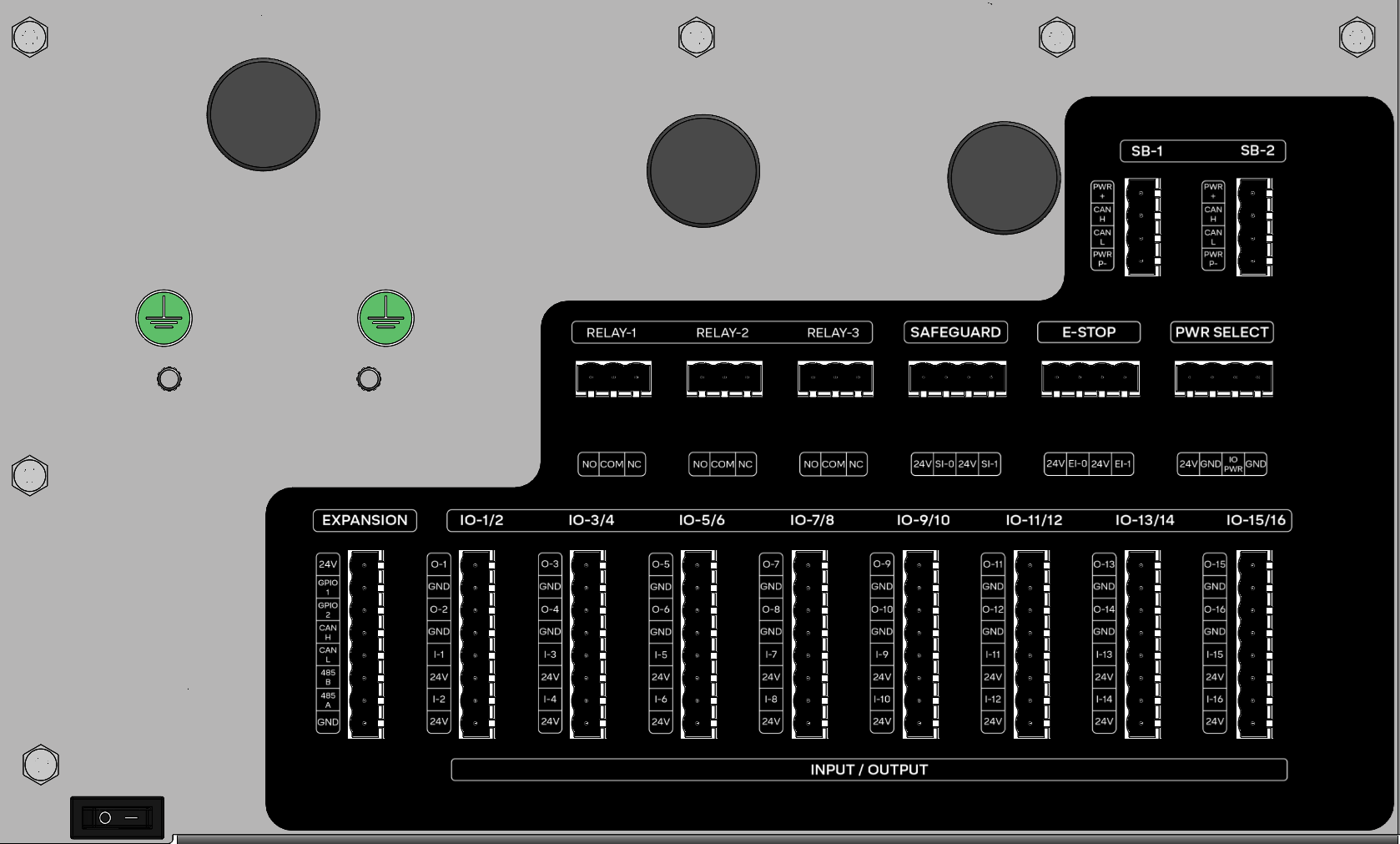

2.2.1 Front Panel

Inside the front panel are many ports that can be used to connect the robot to other equipment in the cell:

| Section | Port Labels | Description |

|---|---|---|

| I/O - 1 and 2 | DI, 24V, GND | This section includes 16 24V I/O ports which can be used to control other equipment in the cell. They are also safety-rated and can be used in pairs to activate safety functions of the robot via the Safety I/O feature. |

| Relay | RL-1, RL-2, RL3 | The relays can be closed to form a circuit and can be used to control equipment in the cell. |

| Safeguard | - | Unsupported. |

| E-Stop | - | This can be hooked up to an external E-stop button. When the input is low, it will force the robot to stop. If no external E-stop button is in use, these ports should have jumpers installed. |

| Motor: | M-1, M-2 | Unsupported. |

| Remote On/Off | ROFF, RON, GND, 24V | Unsupported. |

| Comms | PWR, GPIO 1+2, CAN H, CAN L, 485 A, 485B | Unsupported. Future software will enable communication with other equipment in cell over serial ports. |

2.3 Specs

| Performance | |

|---|---|

| Power consumption | Depends on program and payload. Generally 2-3 amps at 120V. Does not exceed 15 amps at 120V. |

| Collaboration operation | Speed & force limiting per ISO/TS 15066, collision detection, and other safety features |

| Ambient temperature range | 0-55°C |

| Humidity | 90%RH (non-condensing) |

| Specification | |

|---|---|

| Payload capacity | 18kg (39 lbs) maximum. See chart below. |

| Reach | 1.3m (51.2 in) |

| Max joint speed | 435° /s |

| Degrees of freedom | 6 degrees |

| Physical | |

|---|---|

| Footprint | Ø 200 mm |

| Materials | Aluminum, steel, plastic |

| Tool connector type | M8 8-pin & M8 4-pin |

| Cable length, robot arm | 2m (79 in) |

| Weight, including cable | 32.5 kg (71.6 lbs) |

| Robot Features | |

|---|---|

| IP classification | IP54 |

| Noise | Depends on program; typically less than 58dB |

| Robot mounting | Floor mount |

| Flange I/O ports | Digital In: 2 (24V tolerant, 1A max open-drain), Digital Out: 2, tolerant), RS-485 / UART Max data rate: 10mbps |

| I/O power supply in tool | 12V/24V, 3A continuous max |

| Control Box | |

|---|---|

| IP classification | IP54 |

| Ambient temperature range | 0-55°C |

| I/O ports | Digital In: 16 (24V Tolerant), Digital Out: 16 (24V 0.7A Out continuous) |

| Internal I/O power supply | 24V, 3A max continuous. |

| External I/O power supply | 12A Maximum |

| Communication | 24V I/O, Modbus TCP, APIs over Ethernet |

| Power source | 90 ~ 264VAC, 47-63Hz |

| Humidity | 90%RH (non-condensing) |

| Control box size | 483 mm x 385 mm x 270 mm (19.03 in x 15.19 in x 10.65 in ) |

| Weight | 18.5kg (41 lbs) |

| Materials | Powder-coated steel |

| Movement | |

|---|---|

| Repeatability | +/- 0.025 mm |

| Shoulder 1 & 2 | Working range: ±360°, Maximum speed: ±287°/sec |

| Elbow | Working range: ±360°, Maximum speed: ±335°/sec |

| Wrist 1, 2 & 3 | Working range: ±360°, Maximum speed: ±435°/sec |

| Typical TCP speed | 1 m/sec (39.4 in/sec) |

| Maximum TCP speed | 3 m/sec (No payload) |

2.4 Hazardous Energy

2.4.1 Overview

Stored energy is a potential source of danger in many industrial settings. When energy is stored in machines or equipment, it can cause serious injury or death if it is released unexpectedly. This type of hazard is commonly known as hazardous stored energy, and it can take many forms, including electrical, hydraulic, pneumatic, chemical, and mechanical energy.

Some common examples of hazardous stored energy include:

- A compressed air cylinder that has not been properly vented before maintenance or repair work is performed

- A hydraulic cylinder that has not been properly locked out before maintenance or repair work is performed

- A battery that is still connected to a piece of equipment, even though the equipment has been shut down

- A piece of machinery that is still moving, even though the power has been turned off

To protect workers from hazardous stored energy, it is important to follow proper lockout/tag-out procedures. Lockout/tag-out procedures involve shutting off the energy source, isolating the equipment, and securing it with a lock or tag to prevent accidental startup. Before any maintenance or repair work is performed on equipment, workers should always verify that the equipment is properly locked out/tagged out.

/pagebreak

Additionally, workers should receive proper training on lockout/tag-out procedures and the potential hazards associated with hazardous stored energy. They should understand the importance of following these procedures to prevent injuries and fatalities. Employers should also regularly review and update their lockout/tag-out procedures to ensure that they are effective and up-to-date with the latest safety standards.

Remember, hazardous stored energy can be deadly if not properly controlled. By following proper lockout/tag-out procedures and receiving proper training, workers can stay safe on the job and prevent accidents from occurring. /pagebreak

2.4.2 Hazardous Energy in Standard Bots System

Several types of stored energy can exist in a system utilizing a Standard Bots robot:

Electrical: The Standard Bots control box utilizes 120 VAC power as a primary means of power. The control box utilizes electrical devices such as capacitors which store electrical energy even after the control box has been unplugged from the power source. There are no serviceable parts inside Standard Bots control box and it should not be opened except by trained Standard Bots Employees.

Additionally, the Standard Bots RO1 robot also contains capacitors to store electrical energy. The robot should not be opened except by Standard Bots personnel. In some cases it may be required to open the joint caps of the robot. This should only be done after the control box power source has been unplugged for at least 2 minutes, and should only be done while following explicit instructions from Standard Bots personnel.

Mechanical: The Standard Bots RO1 is capable of lifting 39 lbs (18kg). If the robot is stopped mid cycle and currently has a workpiece in the end of arm tool, a hazard will be present as the workpiece could unexpectedly fall if the source providing the clamping force is de-energized. Always exercise caution and remove the workpiece from the end of arm tool when approaching the robot.

Pneumatic: The RO1 is compatible with a variety of pneumatic accessories. Stored energy exists in the form of compressed air in pneumatic systems. Bodily or hearing injury can occur from accidentally releasing compressed air from pneumatic systems while performing maintenance. Unexpected motion can occur from components when working on energized pneumatic systems. All compressed air should be removed from the system before performing maintenance on any pneumatic system.

2.4.3 Performing a Lockout

Should a lockout of the Standard Bots RO1 be required, unplug the AC input cord and use a plug lockout with appropriate lock. Follow all standard lockout tag-out procedures.

If applicable, also lock out any compressed air sources to devices integrated with the RO1 using standard lockout tag-out procedures.

2.5 Anti-Gravity Mode

The RO1 has functionality allowing the user to move the robot to a desired position by manually moving the physical robot instead of jogging the robot with the pendant.

When Anti-Gravity mode is engaged, the robot will compensate for its own weight and set payload to maintain its position without the brakes applied. Additionally, the robot will sense external feedback from the user moving the robot and assist with moving in the desired direction. Provided the payload is set correctly, the robot will move with minimal force applied by the user.

The procedure for using the anti-gravity mode is as follows:

- Ensure you have the desired tooling connected to the robot.

- Navigate to the Move Robot view on the user interface.

- If the robot brakes are not currently applied, click the hexagon icon in the bottom right, then select the “Brake Robot” button.

- Set the payload to the current payload.

- Save the payload.

- Click “Unbrake Robot”.

- Depress the raised button on the end of the robot arm:

- Gently manually maneuver the robot into the desired position while depressing the button.

- In the “Move Robot” view, go to the Space area in the bottom left

menu. The icon is a square.

- Click the plus button to add a position.

- Give the position a name.

- Click “Set” to set the position to the current robot position.

The current robot position is now saved and ready to be used in the routine.

2.6 Movement Without Drive Power

Do not attempt to move the RO1 robot without drive power unless instructed by Standard Bots personnel, otherwise damage could occur.

The RO1 is a collaborative robot, and is designed to work in environments alongside humans. As such, under normal circumstances moving the robot without drive power is not required. Should the robot position need to be changed, simply use pendant to jog the robot into the required position.

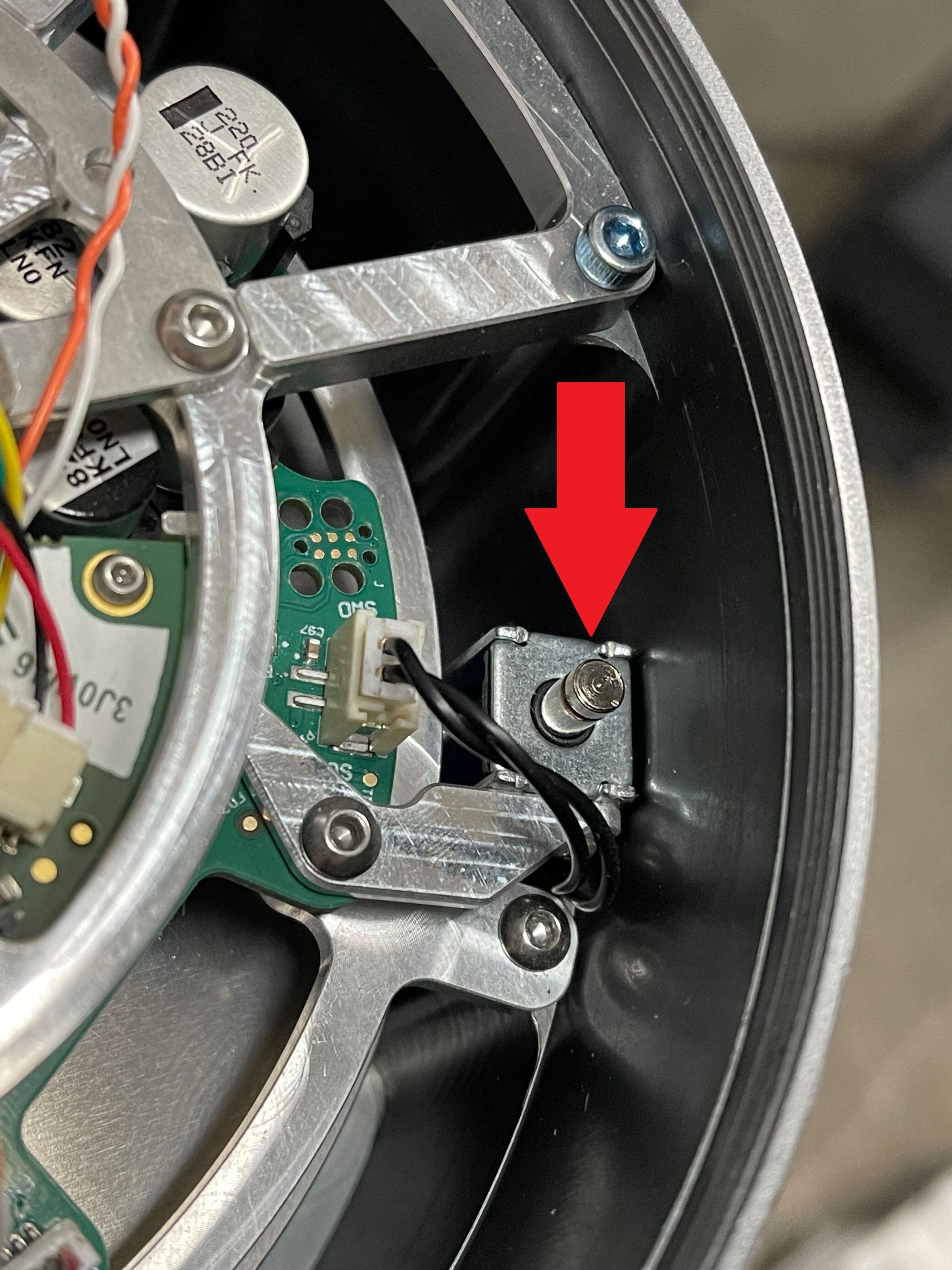

Should you be instructed to move the robot without drive power by Standard Bots personnel, the below procedure can be used on each joint individually to adjust the robot position:

Unplug the robot.

Remove the cover on either Joint 0 or Joint 1 (bottom 2 joints, shown in attached image) by twisting it off.

Press the brake release button (shown in below image) and hold down while moving joint.

Move the robot away from the collision a short distance.

Release brake button.

Replace joint cap.

Plug the robot back in.

Confirm proper robot operation.